Sintered NdFeB maginetiis a alloy magineti yakagadzirwa kubva kuNd, Fe, B nezvimwe zvinhu zvesimbi. Inoshandiswa zvakanyanya mumamini-motor, majenareta emhepo, metres, sensors, vatauri, magineti suspension system, magineti transmission muchina uye mamwe maindasitiri ekushandisa. Zviri nyore kuita ngura munzvimbo dzine hunyoro, saka zvakakosha kuita iyo yepamusoro kurapwa zvinoenderana nezvinodiwa nevatengi. Tinogona kupa machira, akadai seZinc, nickel, nickel-copper-nickel, Silver, gold-plating, Epoxy coating, etc Giredhi: N35-N52, N35M-48M, N33H-N44H, N30SH-N42SH, N28UH-N38UH-N38UH, N28H-N28

Iyo Procession yeSintered Neodymium Magnet Manufacturing

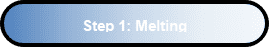

Iwo magineti raw materials uye mamwe masimbi anooneswa kune yepakati frequency uye anonyungudutswa muchoto chekupinza.

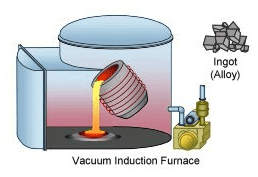

Mushure mekupedzwa kwematanho akasiyana-siyana ekuita, ingots inotemwa kuita zvimedu zvine akati wandei mamicrons muhukuru. Kuti udzivise oxidation kuti irege kuitika, zvidimbu zvidiki zvinodzivirirwa nenitrogen.

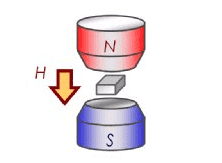

Iwo magineti particles anoiswa mujig uye magnetic field inoshandiswa apo magineti anomanikidzwa kuita maumbirwo kunyanya. Mushure mekutanga kuumbwa, oiri isostatic kudzvanya inoenda mberi kuumba zvimiro.

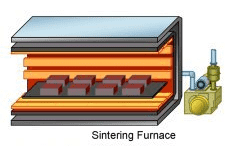

Iwo magineti particles anoiswa muingots akatsikirirwa uye achave nekupisa kurapwa muchoto chinopisa. Kuwanda kweiyo ingots yekutanga inongorova 50% yechokwadi density kune sintering. Asi mushure mekunyura, density yechokwadi ndeye 100%. Kuburikidza nemaitiro aya, kuyerwa kweingots kunenge kuderera 70% -80% uye huwandu hwayo hunoderedzwa ne50%.

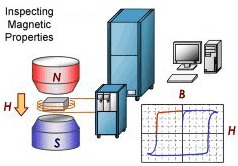

Basic magineti zvivakwa zvakaiswa mushure mekunge sintering uye kuchembera maitiro apera. Izvo zviyero zvikuru zvinosanganisira remnant flux density, kumanikidza, uye yakanyanya simba chigadzirwa zvinorekodhwa.

Iwo chete magineti akapfuura ongororo anotumirwa kune anotevera maitiro, senge machining uye kuunganidza.

Nekuda kwekuderera kubva mukuita sintering, zviyero zvinodiwa zvinowanikwa nekukuya magineti nemaabrasives. Madhaimondi abrasives anoshandiswa pakuita uku nekuti magineti akaomarara.

Kuti ikwane zvakanyanya nharaunda yaachazoshandiswa, magineti anoiswa kune akasiyanapamusoro mishonga. Nd-Fe-B magineti anowanzo batwa ne ngura nechitarisiko chinobatwa seNiCuNi magineti, Zn, Epoxy, Sn, Black Nickel.

Mushure mekuputira, zviyero zvine hukama uye ongororo yekuona ichaitwa kuratidza yedu magineti chigadzirwa chitarisiko. Kunze kwezvo, kuti tive nechokwadi chepamusoro, isu tinoda zvakare kuyedza saizi kudzora kushivirira.

Kana kutaridzika uye saizi kushivirira kwemagineti kwakakodzera, yave nguva yekuita magineti kutungamira.

Kutevera kuongororwa uye magnetize, magineti akagadzirira kurongedza nebepa bhokisi, kunyange mapuranga pallet sezvinodiwa nevatengi. Magnetic Flux inogona kupatsanurwa nesimbi yemhepo kana kuburitsa izwi rekutaura.

Nguva yekutumira: Jan-25-2021